125 -150 Cbm Vertical Steel Lined Plastic (LLDPE) Storage Tank for HCl (max 35%) , Naoh (max 50%) , Naclo (max 10%) , H2so4 Chemical Liquid Corrosion Resistance

Overview 125 CBM Vertical Steel Lined Plastic (LLDPE )Storage Tank For HCl (max 35%), NaOH (max 50%), NaCLO (max 10%), H

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | HCl Storage Tank |

| After-sales Service | 24 |

| Warranty | 24 |

| Condition | New |

| Customized | Customized |

| Tank Marerial | Metal Tank |

| Type | Horizontal / Vertical |

| Storage Objects | Liquid |

| Materical | Q235A + PE (Plastic )16mm -22mm |

| Type H | Horizontal / Vertical |

| Transport Package | Nil |

| Specification | OEM |

| Trademark | Dong Run Ze |

| Origin | China |

| HS Code | 73090000 |

| Production Capacity | 8000 |

Product Description

Steel Lined Plastic LLDPE Vertical Flat Bottom Steel Lined Plastic LLDPE Tank For Storage HCl (max 35%) , Naoh (max 50%) , Naclo (max 10%)

Electrolytic Polishing Tank / Can /Pool Pipe Unit, Electrolytic Cleaning Tank,Acid Polishing Tank

Metal cans Steel-Lined Plastic Square Tank, Electrolytic Tank, Pickling Tank Acid Containment Vessels Custom Made Rotationally Molded Linear Resins LLDPE

Custermizing Checmial Acid Storage Tank 1-150 m3 Steel Lined LLDPE Tank Used to Contain: HCl (max 35%) , Naoh (max 50%) , Naclo (max 10%) , PAC (max 17%) ,H2so4

Used to contain: HCl (max 35%), NaOH (max 50%), NaCLO (max 10%), PAC (max 17%), H2SO4 etc

Media (density) : (1155 Kg/m3), Hydrochloric Acid (1150 Kg/m3), Sulfate, Nitrate (1152 Kg/m3), Phosphate (1151 Kg/m3), Hydrofluoric Acid (1132 Kg/m3), Battery Fluid (1135 Kg/m3), Chloride (1135 Kg/m3), Ferric Chloride Solution (1130 Kg/m3), Sodium Hypochlorite (1130 Kg/m3), Sulfurous Acid (1030 Kg/m3)

processing/storing; aluminum sulfate, ammonium sulfate, calcium chloride, ethylene glycol, ferric chloride, ferric sulfate, ferrous sulfate, hydrochloric acid, hydrofluoric acid, hydrofluosilicic acid, hydrogen peroxide, magnesium chloride, phosphoric acid, polymers, potassium hydroxide, or just plain water and we'll design the vessel(s) you require.

Horizontal / Vertical Storage HCL Acid Tanks Steel Lined LDPE

For Storage Bleach, Hydrochloric Acid, Ferric Chloride, Oilfield Chemicals, Corrosive Wastes And Other Hazardous Cargoes.

Steel ( 6 mm -8mm ) Lined PE Plastic 7042 (16mm - 25 mm ) storage tank

Steel Lined LDPE aslo for Steel Lined LDPE Tank aslo for HCL(max 35%), NaOH (max 50%), NaCLO (max 10%), PAC (max 17%),H2SO4(60%,98%) ,HF (48%),H3PO4 (10%-85%),NH3. H2O,H2O2 (30%) Hazardous LiquidsTank Container

Steel Lined LDPE aslo for HCL(max 35%), NaOH (max 50%), NaCLO (max 10%), PAC (max 17%),H2SO4(60%,98%) ,HF ( 48%),H3PO4 (10%-85%),NH3. H2O,H2O2 (30%)

Compounds, cleaning liquid, UN1760,

Corrosive liquid, acidic, inorganic, n.o.s., UN3264,

Corrosive liquid, acidic, organic, n.o.s., UN3265,

Corrosive liquid, basic, inorganic, n.o.s., UN3266,

Hypochlorite solutions, UN1791,

Hydrochloric acid solution, UN1789,

Sulfuric acid, UN2796,

BATTERY FLUID, ALKALI UN 2797,

Detail Picture

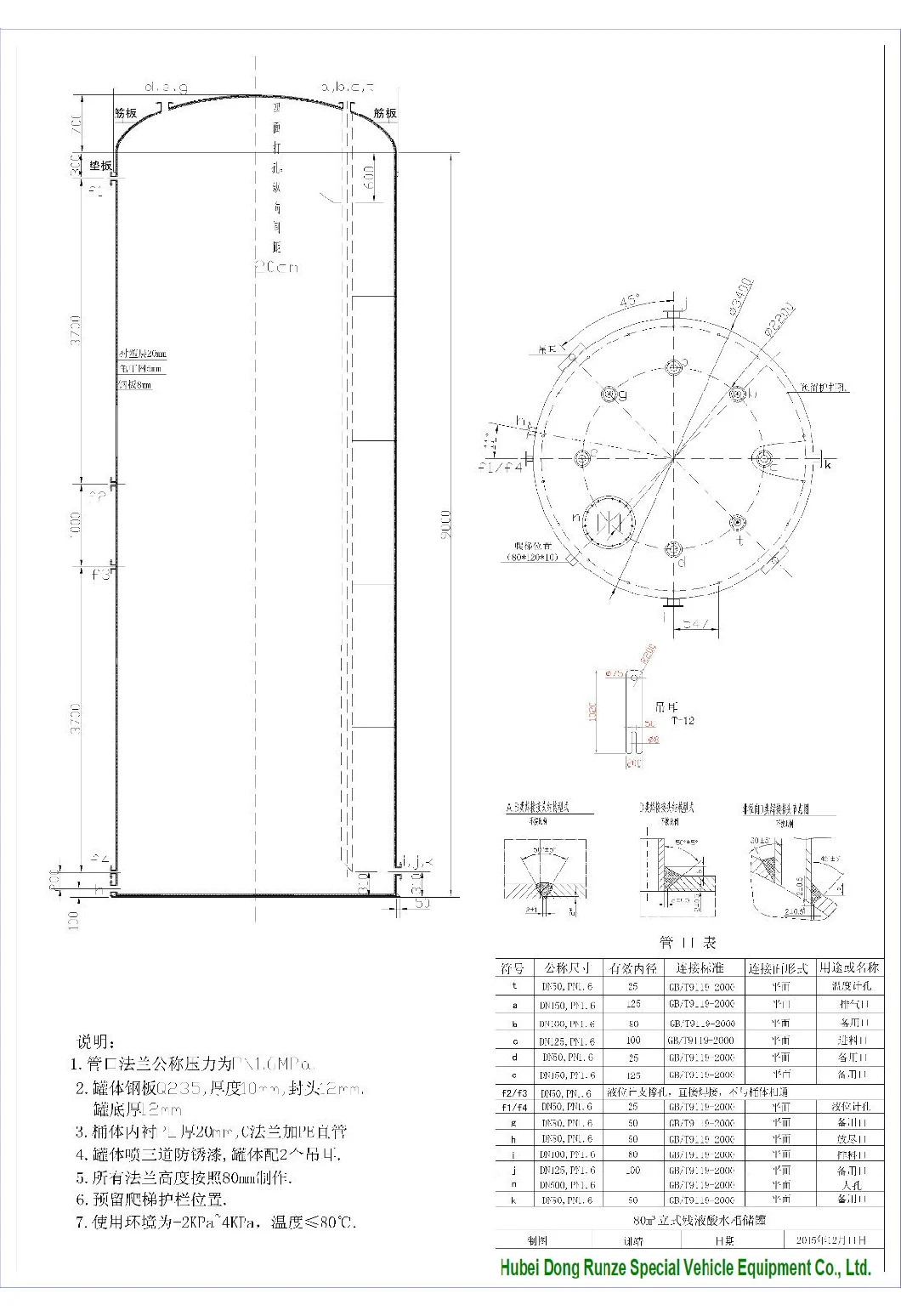

Vertical Bleach Sodium Hypochlorite ,Hydrochloric Acid Storage 125m3 (125,000L) Draft

Steel Lined LLDPE Tank

Vertical Bleach Sodium Hypochlorite ,Hydrochloric Acid Steel Lined LLDPE Tank Storage 150m3 (150,000L) Draft

Vertical Bleach Sodium Hypochlorite ,Hydrochloric Acid Steel Lined LLDPE Tank Storage 100m3 (100,000L) Draft

Vertical Hydrochloric Acid Storage Tanks ,Dosing tank, Day tank 30cbm (30000L) Draft

Vertical Bleach Sodium Hypochlorite ,Acid Storage Dosing Tanks 10cbm (10000L) Draft

Vertical Bleach Sodium Hypochlorite ,Acid Dosing Tanks , measuring tank 5m3 (5000L) Draft

Vertical Bleach Sodium Hypochlorite ,Acid Dosing Tanks , measuring tank 2m3 (2000L) Draft

metering tank Vertical HCl Storage Tanks 90cbm (90000L ,23775Gallon) Draft

Vertical Hydrochloric Acid Storage Tanks 50cbm (50000L) Draft

Vertical Hydrochloric Acid Storage Tanks 30cbm (30000L) Draft

Vertical Hydrochloric Acid Storage Tanks 15cbm (15000L) Draft

Vertical Hydrochloric Acid Storage Tanks 10cbm (10000L) Draft

Vertical Hydrochloric Acid Storage Tanks 5000L Draft

Certifications

Packaging & Shipping

FAQ

1.Are you trading company or manufacturer ?

We are Group Corporation manufacturer ,have Group Factories Contractor.2 .Can I have samples of this type of product to test the quality?

Yes, you can buy any sample to test the quality,our MOQ is 1 unit.

3. What's the delivery time and can you lower the price?

It depends on your order.The delivery time is within 30 workdays after we received your prepayment. If you have placed an order of large quantities, then,of course, the price can be lowered.

4.Can you supply some quick-wear parts?

Yes, we can supply the parts as your request,such as traction,traction pin,balance beam and plate spring,hanging accessories,turntable,all kinds of brake pads,brake pan, bearings,etc.6.Do you have any used products for sale?

We have products in stock for choices,the prices are favorable,we'll show you our stock products if you need.7.What's the payment terms?

TT 30% as deposit, balance before shipment by TT or at sight.8. How to guarantee customers get the goods smoothly after they payment?

Don't worry,dear.We have joined the trade assurance,you can place the order by trade assurance,if we don't delivery products, the deposit will be returned to you.

9.How can you ensure the quality of the products?

Don't worry,dear.We have joined the trade assurance,if the products have quality problems when you received them,the payments can be refund to you.

There are five commonly used wrecker tow truck , usually depending on the type or size of the recovery wrecker :

First type : Boom towing truck

- use adjustable arms and winches to retract vehicles from ditches, embankments, or any vehicle that cannot arrive safely. Some booms are fixed, some heavy rotating racks, hydraulic telescopic tubes, others. In the past boom, trucks used the "hook chain" system, the chain around the frame or axle, and then hoisted by the winch. A heavy rubber pad is attached to the truck and truck so that it can be towed onto other bridges." Slings and belts are an evolution, replacing parts of chains with rubber belts. slings did not use too much today because they could shave bumper cars. But they are sometimes used in wrecker accidents carrier or have one or two front wheels or rear wheels missing or pickups and other vehicles have steel bumpers. Equipped with all wheel drive, the truck is towed away, unable to use the machine string, because it can make the car power transmission system problems.

Second type :Wheel lift wrecker towing truck

(also called "glasses") - from the chain hook technique to generate a large metal frame, can be installed in the front or rear under the cradle, rendering vehicles by pneumatic or hydraulic hoist can drag the ground clear front or rear. The device usually picks up the wheel of the vehicle (i.e., front wheel, if it is front wheel drive, rear wheel, if it is rear wheel drive), and contacts the tire. wheel lift wrecker tow truck are common in china; cradles are like glasses. Medium and heavy-duty trucks use variations, "underlift" or "chassis lift", in which the elevator shaft or frame is not the wheel. A forklift truck can be used as an adapter or a lift chassis.

Third type :Integration towing truck (also known as "Self Loader wrecker equipment", "Snatcher towing vehicle", "quick choice tow truck" or "roll back wrecker") - the arm and wheel lift together. Used of light trucks to recover or stop vehicles. Most of the truck's cab equipment is controlled so that the pickup truck does not leave the truck to connect the vehicle. heavy trucks are also manufactured using integrated lifts.

Forth type --Flat plates wrecker truck (also known as "rolling back tow truck" or "sliding tow truck") - the entire back of the truck is fitted with a bed that can be hydraulically tilted down to the ground, allowing the vehicle to be placed under its own power or pulled up by the winch. [9] because they carry, rather than traction vehicles, it can be completely fixed; in the United States, they carry serious damage to car accidents.

Fifth type ---Lifting platform wrecker truck the derricks lift the vehicle vertically and use the wheel lift to load it on the bed. In Europe, this car can eliminate the parallel parking of vehicles.

Concentrated sulfuric acid storage tank

Hydrochloric acid storage tank

Nitric acid storage tank

Sodium hypochlorite storage tank

Ammonia tank

Methanol tank

Hydrogen peroxide storage tank

Sodium hydroxide tank

Storage tank for additives

Polycarboxylic acid storage tank

Urea tank

Rotationally Molded LLDPE TANK chemical resistance of LLDPE Cell / :+8615271357675

tictrucks.en.made-in-china.com

LDPE / HDPE Chemical Resistance Chart

The chemical compatibility of LDPE and HDPE on this chart is tested at 20°C: and 50°C: for 7 days and 30 days (if applicable) with constant exposure.

| LDPE & HDPE resistance listed by chemical | |

| 1.4-dioxane | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE at 50°C: shows some effect after 7 days. |

| Acetaldehyde | LDPE / HDPE at 20°C: little or no damage after 30 days. HDPE at 50°C: shows some effect after 7 days. LDPE at 50°C: immediate damage may occur. |

| Acetic Acid 5 % | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Acetic Acid, glacial 50% | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE at 50 °C: immediate damage may occur. |

| Acetone | LDPE / HDPE at 20°C-50°C: damage may occur. Not recommended for continuous use. |

| Allyl Alcohol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Aluminum salts | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Amino acids | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ammonia | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ammonium carbonate saturated | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ammonium phosphate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ammonium sulphate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Amyl chloride | HDPE at 20°C: shows some effect after 7 days. HDPE at 50°C & LDPE at 20°C-50°C: immediate damage may occur. Not recommended for continuous use. |

| Aniline | LDPE / HDPE at 20°C: little or no damage after 30 days. HDPE at 50°C: shows some effect after 7 days. |

| Benzene | LDPE / HDPE at 20°C-50°C: damage may occur. Not recommended for continuous use. |

| Benzyl alcohol | LDPE / HDPE at 50°C: immediate damage may occur. HDPE at 20°C: shows some effect after 7 days. |

| Boric acid | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Bromine | LDPE / HDPE at 50°C: immediate damage may occur. HDPE at 20°C: shows some effect after 7 days. |

| Butyric acid | LDPE / HDPE at 50°C: immediate damage may occur. HDPE at 20°C: shows some effect after 7 days. |

| Calcium chloride | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Calcium hydroxide saturated | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Carbon tetrachloride | HDPE at 20°C: shows little or no damage after 30 days. LDPE at 20°C & HDPE at 50°C: show some effect after 7 days. LDPE at 50°C: not recommended. |

| Chlorine 10% in water | LDPE / HDPE at 20°C: shows little or no damage after 30 days. LDPE at 50°C: shows damage and is not recommended. |

| Chlorobenzene | Immediate damage may occur. Not recommended for continuous use. |

| Chloroform | LDPE / HDPE at 20°C: show some effect after 7 days. LDPE / HDPE at 50°C: immediate damage may occur. Not recommended for continuous use. |

| Chromic acid 10% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Chromic acid 50% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Citric acid 10% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Cresol | HDPE at 20°C: shows some effect after 7 days. LDPE at 20°C-50°C & HDPE at 50°C: show immediate damage. Not recommended for continuous use. |

| Cyclohexane | LDPE / HDPE at 50°C: immediate damage may occur. LDPE / HDPE at 20°C: show some effect after 7 days. |

| Diethyl ketone | LDPE / HDPE at 20°C-50°C: damage may occur. Not recommended for continuous use. |

| Dimethylsulfoxide | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ethanol 95% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ethyl acetate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ethyl benzene | HDPE at 20°C: shows some effect after 7 days. LDPE at 20°C-50°C & HDPE at 50°C: show immediate damage. Not recommended for continuous use. |

| Ethylene glycol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Ethylene oxide | HDPE at 20°C: shows little or no damage after 30 days. LDPE at 20°C: and LDPE/ HDPE at 50°C: show some effect after 7 days. |

| Ferric chloride | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Fluoride | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Fluorine | HDPE at 20°C: shows little or no damage after 30 days. LDPE at 20°C: shows some effect after 7 days. Not recommended at 50°C. |

| Formaldehyde 10% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Formaldehyde 40% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Glycerol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hexane | HDPE at 20°C: shows little or no damage after 30 days continuous use. HDPE at 50 °C: shows some effect after 7 days. LDPE not recommended at any temperature. |

| Hydrochloric acid 20% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrochloric acid 35% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrochloric acid 5% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrocyanic acid | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrofluoric acid | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrofluoric acid 4% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrofluoric acid 48% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrogen peroxide 3% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Hydrogen peroxide 30% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Isobutyl alcohol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Isopropyl alcohol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Kerosene | LDPE / HDPE at 20°C: show some effect after 7 days. LDPE / HDPE not recommended at 50°C, as immediate damage may occur. |

| Lactic Acid 10 % | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Lactic Acid 90 % | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Lead acetate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Methanol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Methyl ethyl ketone | Immediate damage may occur. Not recommended for continuous use. |

| Methyl propyl ketone | HDPE at 20°C: shows some effect after 7 days. LDPE at 20°C-50°C & HDPE at 50°C: Immediate damage may occur. Not recommended for continuous use. |

| Methylene chloride | HDPE at 20°C: shows some effect after 7 days. LDPE at 20°C-50°C & HDPE at 50°C: Immediate damage may occur. Not recommended for continuous use. |

| Mineral oil | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE at 50°C: may show immediate damage and is not recommended. |

| n-amyl acetate | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE at 50°C: shows some effect after 7 days or constant exposure. |

| n-butyl alcohol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Nitric acid 50 % | LDPE at 20°C: shows little or damage after 30 days. HDPE at 20°C & LDPE at 50°C: show effect after 7 days. HDPE at 50°C: shows immediate damage and is not recommended. |

| Nitric acid 70 % | LDPE / HDPE at 20°C: show some effect after 7 days. LDPE / HDPE at 50°C: show immediate damage. Not recommended. |

| n-octane | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Oleic acid | HDPE at 20°C-50°C: little or no damage after 30 days. LDPE at 20°C-50°C: shows immediate damage and is not recommended. |

| Oxalic acid | LDPE at 20°C: shows some effect after 7 days. HDPE at 20°C and LDPE / HDPE at 50°C: shows little/ no damage after 30 days. |

| Ozone | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE / HDPE at 50°C: show immediate damage. Not recommended. |

| Perchloric acid | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE / HDPE at 50°C: show immediate damage. Not recommended. |

| Perchloric ethylene | LDPE / HDPE at 20°C-50°C: show immediate damage. Not recommended. |

| Phenol | LDPE / HDPE at 20°C-50°C: show immediate damage. Not recommended. |

| Phosphoric acid 10% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Phosphoric acid 85% | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE at 50°C: shows immediate damage and is not recommended. |

| Phosphorous trichloride | LDPE / HDPE at 20°C: little or no damage after 30 days. LDPE at 50°C: has no data available. HDPE at 50°C: shows some effect after 7 days. |

| Potassium carbonate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Potassium hydroxide 5 % | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Potassium hydroxide concentrated | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Potassium permanganate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Propylene glycol | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Pyridine | Immediate damage may occur. Not recommended for continuous use. |

| Salicylic acid, saturated | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Silver acetate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Silver nitrate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sodium carbonate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sodium chloride, saturated | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sodium dichromate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sodium hydroxide 1% | LDPE at 20°C-50°C: shows little or no damage after 30 days. HDPE at 20°C-50°C: shows some effect after 7 days. |

| Sodium hydroxide 50% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sodium hypochlorite 15% | HDPE at 20°C-50°C: little or no damage after 30 days. LDPE at 20°C: is suitable but at 50°C: shows some effect after 7 days. |

| Sodium nitrate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sodium sulphate | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sucrose | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sulfuric acid 20% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sulfuric acid 6% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sulfuric acid 60% | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Sulfuric acid 98% | LDPE at 20°C-50°C: shows little or no damage after 30 days. HDPE at 20°C: shows effect after 7 days. Not recommended for use at 50°C. |

| Tannic acid | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Tetrahydrofuran | LDPE / HDPE at 20°C: show some effect after 7 day of constant exposure. LDPE / HDPE at 50°C: show immediate damage. Not recommended. |

| Toluene | LDPE at 20°C: show some effect after 7 day of constant exposure. HDPE at 20°C-50°C & LDPE at 50°C: show immediate damage. Not recommended. |

| Trichloracetic acid | LDPE / HDPE at 20°C: show some effect after 7 day of constant exposure. LDPE / HDPE at 50°C: show immediate damage. Not recommended. |

| Trichlorethane | Immediate damage may occur. Not recommended for continuous use. |

| Turpentine oil | LDPE / HDPE at 20°C: show some effect after 7 days. LDPE / HDPE at 50°C: show immediate damage. Not recommended. |

| Urea | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

| Xylene | HDPE at 20°C: shows some effect after 7 day of constant exposure. LDPE at 20-50°C and HDPE at 50°C: show immediate damage. Not recommended. |

| Zinc chloride | LDPE / HDPE at 20°C-50°C: little or no damage after 30 days. |

Related Products

-

![Efficient Falling Film Ethanol Extraction Machine Vacuum Evaporator]()

Efficient Falling Film Ethanol Extraction Machine Vacuum Evaporator

-

![Water Treatment Falling Film Multi Effect Forced Circulation Mvr Evaporator Concentration Equipment]()

Water Treatment Falling Film Multi Effect Forced Circulation Mvr Evaporator Concentration Equipment

-

![First Class Industrial Steam Distillation Essential Oil Ethanol Extraction Etanol Machine Steam Distilation Distilation Tower]()

First Class Industrial Steam Distillation Essential Oil Ethanol Extraction Etanol Machine Steam Distilation Distilation Tower

-

![SS304 Fractionating Column/Distillation Column/Cooling Tower for Pharmaceutical Industry]()

SS304 Fractionating Column/Distillation Column/Cooling Tower for Pharmaceutical Industry