SS304/316 Stainless Steel Sanitary Grade Sterile Vacuum Milk Insulated Vertical Reaction Kettle with Stirring Machine

Overview Package size per unit product 20.00cm * 30.00cm * 20.00cm Gross weight per unit product 5.000kg Lead Time 7 day

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | JN-ST 1001 |

| After-sales Service | All The Time |

| Warranty | 3 Years |

| Process | Mild Processing |

| Power Source | Electric |

| Certification | CE, ISO9001 |

| Automatic Grade | Semi-Automatic |

| Application | Milk, Yogurt, Milk Powder, Cheese |

| Customized | Customized |

| Material | SS304, SS316L |

| Sealing Material | Silicone, EPDM, Viton, PTFE, or NBR |

| MOQ | 1PCS |

| Acting Mode | Electrical, Steam Heating |

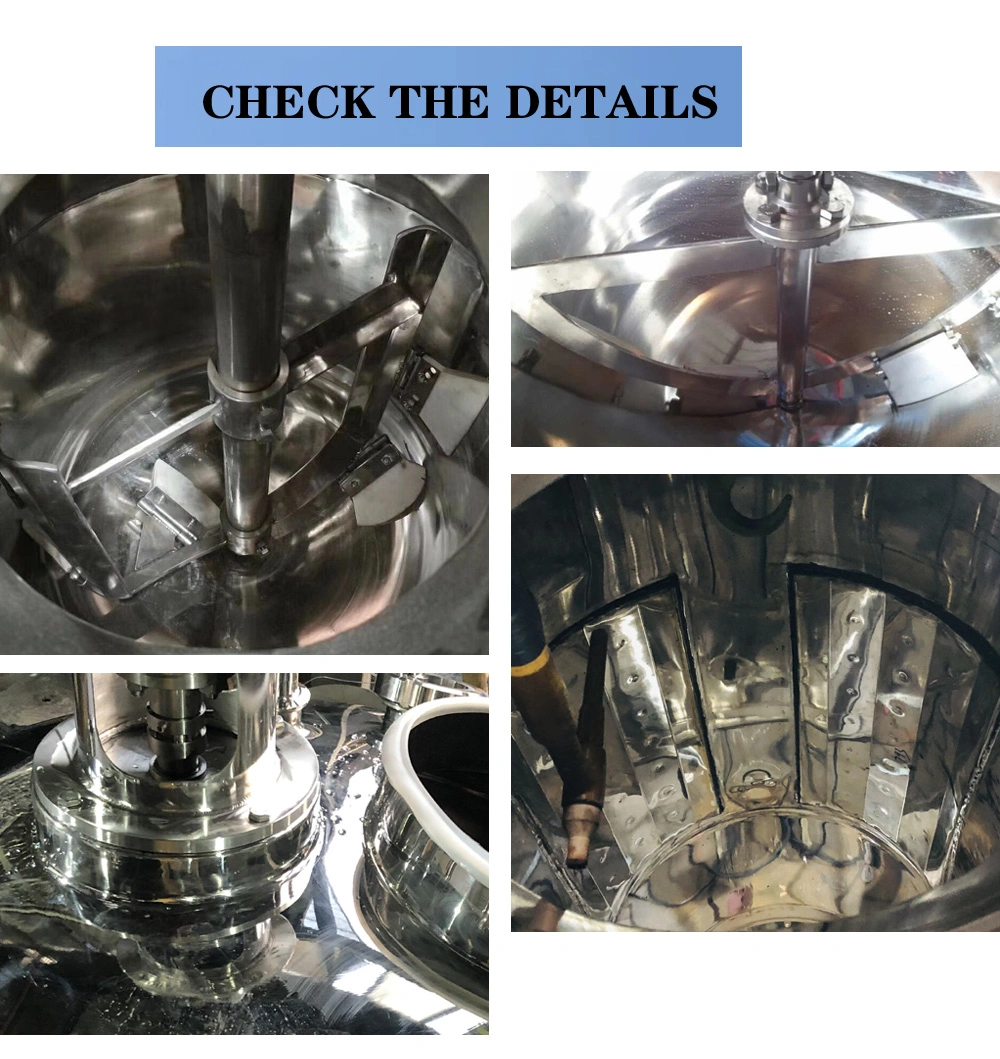

| Surface Finish | Ra 0.5 |

| Connection | Weld, Clamp, Male, Female, Union, Flange |

| Mixing Type | Agitator |

| HS | 8479820090 |

| Capacity | 50sets/Month |

| Transport Package | Wooden Case |

| Specification | 50-1000L |

| Trademark | EZO |

| Origin | Wenzhou, China |

| HS Code | 8479820090 |

| Production Capacity | 200PCS/Month |

Packaging & Delivery

Package size per unit product 20.00cm * 30.00cm * 20.00cm Gross weight per unit product 5.000kg Lead Time 7 days (1 - 10 Pieces)To be negotiated ( > 10 Pieces)

Product Description

SS304/316 Stainless Steel Sanitary Grade Sterile Vacuum Milk Insulated Vertical Reaction Kettle With Stirring Machine

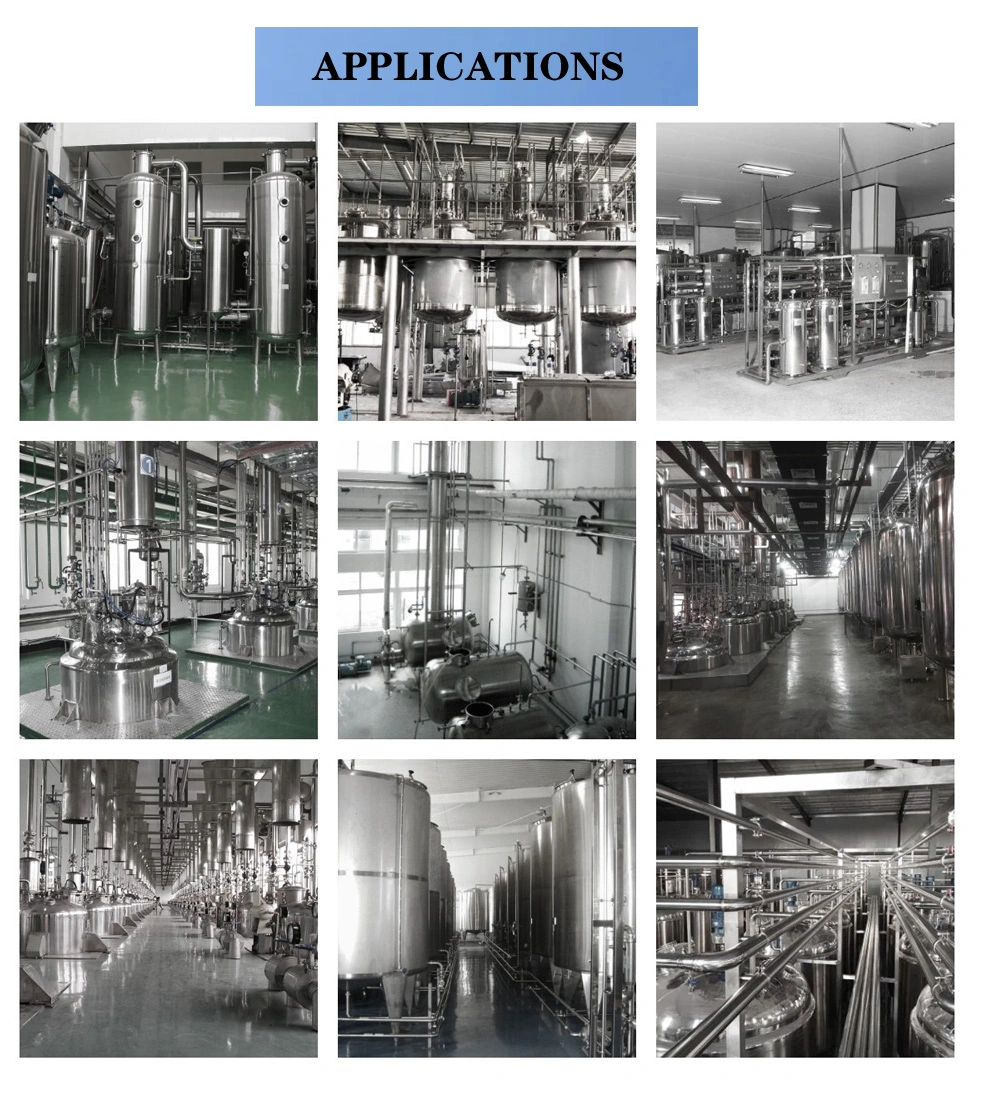

Stainless steel jacket kettle is an ideal equipment for food processing, like sugar, medicine, dairy, cake, fruit, sauced meat, vegetables, condiments, jam, etc. The tank is also a very good choice for heating ,mixing and concentrating viscosity food in pharmaceutical and chemical industry.

The jacket kettle is composed of kettle , worm whee, support, heating jacket or steam jacket. The jacket is equipped with electric heating rod, transfer oil and thermocouple( built-in system ). The jacket kettle is controlled by the control box . A mixing system can be installed which can be considered.

The jacket kettle is made of stainless steel. The electrical components can be considered to short the heating time . Or we can consider the dimple jacket inside the tank which is also very good for steam heating.

The advantages of the jacket kettles is as below

1. small space

2. efficient heating area

3. fast heating

4. uniform heating

5. good control for heating temperature

We have lots of different tanks for application: storage tank, mixing tank, fermentation tank, emulsifer tank . So different functions can be available, mixing, blending, dissolving, heating, cooling, circulation. Application :dairy products, food, fruit, pharmacy , chemical, beverage, bio-engineering, pharmacy, meticulous chemical industry,

| Model | Volume-L | Diameter-mm | Power | L | W | H | Power | Heating area | Speed RPM |

| EZO-50 | 50 | 550 | 3.75 | 930 | 580 | 820 | 0.75 | 0.2 | 36 |

| EZO-100 | 100 | 700 | 12.75 | 1080 | 725 | 870 | 0.75 | 0.45 | 36 |

| EZO-150 | 150 | 750 | 15.75 | 1030 | 780 | 895 | 0.75 | 0.76 | 36 |

| EZO-200 | 200 | 800 | 18.75 | 1180 | 865 | 915 | 1.5 | 1 | 36 |

| EZO-300 | 300 | 900 | 24.75 | 1320 | 970 | 960 | 1.5 | 1.15 | 36 |

| EZO-400 | 400 | 1000 | 24.75 | 1540 | 1120 | 1050 | 1.5 | 1.44 | 36 |

| EZO-500 | 500 | 1150 | 24.75 | 1640 | 1170 | 1110 | 2.2 | 1.9 | 23 |

| EZO-600 | 600 | 1200 | 27.75 | 1700 | 1240 | 1200 | 2.2 | 2.4 | 23 |

| Material | SS304, SS316L | ||||||||

| working pressure | 0.3Mpa | ||||||||

| Volume | 50-1000L | ||||||||

| Surface | Mirror polished or matte polished | ||||||||

| Heating type | electrical heating, steam heating | ||||||||

| Agitator type | Paddle mixer | ||||||||

| Parts | CIP cleaning balls, sanitary valve, electric box, thermometer , cover , mixer type | ||||||||

ABOUT OUR COMPANY

| Ezo stainless steel company was started in 2007. Located in the stainless steel industry zone, Wenzhou, China. |

| Totally 145nos of workers and the factory Covers 6800m2. Till now, we have 40 sets of LG Mazak machines and other local CNC machines; Plus, we have 2 sets of automatic machining unit. To assure better quality, we have the full inspecting quality control equipment: 1nos Ra roughness instrument, 3nos stainless steel spectrometer, numbers of roundness instrument, numbers of thickness instrument, numbers of radius instrument, 3 nos pressure testing center. |

| Ezo stainless steel provides the following tanks: Stainless steel storage tank, mixing tank, extracting tank, evaporator, concentration units, fermenting tank, plate sterilizer, CIP cleaning system, heat exchangers stainless steel sanitary filters ( Y filter, inline filter, L filter, housing filter Stainless steel Sanitary pump ( stainless steel sanitary centrifugal pump, rotary lobe pump, CIP pump) Stainless steel sanitary manways ( Pressure type manway, non pressure manway, round manway, rectangular manway |

| Ezo stainless steel services for food, beverage, dairy, chemical, bioth, pharmaceutical, and etc industries. |

| Ezo stainless steel customers are from 55 different countries.After so many years, Ezo knows more about different requirements from different countries' customers. Ezo stainless steel believes in "What we say, what we do". We always believe honesty and responsibility is the only way leading to long term business relationship. Trying our best for customers and put ourselves into customers' shoes. Our commitment " Never let customers leave us because our poor quality". Making business with us, making friends with us. |

OUR INSPECTION

| HOW DO WE MAKE THE QUALITY CONTROL | |

| For Raw Materials | 1. Material control from raw materials. For raw material checking, we check 100% by chemical liquid. Any property mistakes would be rejected. 2. Sand hole inspection after raw materials are machining before polishing. 3. Carbon component report can be provided if needed 4. Mechanics test report can be provided if needed |

| For New products | 5. 2nos of new samples to be checked against technical drawing. Testing report is provided to customers before bulk production. |

For finished materials | 6. For valves, pressure testing and temperature testing is required for each valve. 7. After we get the finished products, we check for surface roughness, thickness equality, roundness, size measurement and sand holes again. 8. For all finished products, the checking quantity is not less than 10% of total quantity. 9. Before shipment, we check for the quantity of each product in order to find out any missing quantity or wrong product. |

FAQ:

1. Are you a trading company or factory?

We are a manufacturer factory and we also have our own exporting license.

2. Do you have certificate ?

Yes, ISO, FDA, LFGB, CE, PED certificate . We also have some patents in design.

3. How do you control the quality?

In quality control ,the most important is to avoid material mixing .

In our factory , 3 spectro PMI machines are used in raw material warehouse, production plant, dispatch plant.

Pressure inspecting machine, PMI machines, RA roughness spector, hardness testing machine..... all machines help in inspection.

2 staff inspect during production in different sections

5 staff inspect the finished productions to avoid shortage, poor quality, mixing chemical....

4. If there is any quality problem, how do you solve it?

We are very proud that we never make one customer leave us. We are not 100% perfect, there is some quality problem.

Normally replacement, or compensation, or resend goods to customers as per the condition. To be discussed as per condition.

5. How long is your delivery time?

For normal products in 7-10 days; for bulk order, in 15-25 days. It depends.

6. Warranty time?

3 years warranty for all of our stainless steel products. Gaskets or the easy broken parts are not included due to the different application for customers.

7. Why trust in us ?

14 years in this industry . It makes us professional .Good credit in this market.

All of our machines are the assurance of our responsibility.

8. Free sample ?

Free samples can be provided for first cooperation under sincere cooperation.

9. What is the MOQ?

1pcs MOQ is welcome for starting cooperatoon

10.Material certificate ?

Material certificaite, mill certificate, pressure testing certificate, roughness certificate, measure certificate, RT certificate,... can be available, please declare when inquiry us.

11. More questions are appreciated.

Related Products

-

![Pharmaceuticals Chemicals Agitated Nutsche Filter Dryer]()

Pharmaceuticals Chemicals Agitated Nutsche Filter Dryer

-

![High Quality Stainless Steel GMP Vacuum Agitated Nutsche Filter Dryer]()

High Quality Stainless Steel GMP Vacuum Agitated Nutsche Filter Dryer

-

![The Stainless Steel Top Feeding Brewer′ S Yeast/ Feed Yeast/Food Yeast/Fruit Pulp Drum Dryer/Spray Dryer/Flash Dryer/Vacuum Dryer]()

The Stainless Steel Top Feeding Brewer′ S Yeast/ Feed Yeast/Food Yeast/Fruit Pulp Drum Dryer/Spray Dryer/Flash Dryer/Vacuum Dryer

-

![Used 1600 Type Alcohol Recovery Tower, Distillation Extraction Tower, Solvent Distillation Tower, Distillation Distillation Tower, Packing Tower Section]()

Used 1600 Type Alcohol Recovery Tower, Distillation Extraction Tower, Solvent Distillation Tower, Distillation Distillation Tower, Packing Tower Section